At its heart, the risk assessment process is a structured way for organisations to identify potential dangers, figure out the risks they pose, and then put sensible controls in place to manage them. It’s all about being proactive—tackling issues to prevent harm, keep people safe, and ensure the business runs smoothly before something goes wrong.

Table of Contents

Deconstructing the Core Concepts of Risk Assessment

To really get what a risk assessment process is, you need to break it down into a few simple ideas. This isn’t some complex, bureaucratic chore; it’s a practical, logical way to protect your business and your people.

Think of it like planning a long road trip. You wouldn’t just jump in the car and start driving. You’d check the tyres, map your route, and look out for potential problems like road closures or bad weather. That’s risk assessment in a nutshell.

This forward-thinking mindset is what it’s all about. It involves looking ahead to spot what could go wrong and getting ready for it. This simple act of foresight is vital for any organisation, whether it’s a tech startup or a massive manufacturing plant.

Hazard vs. Risk: A Crucial Distinction

To do a proper assessment, you have to get one thing straight: the difference between a hazard and a risk. People mix these up all the time, but they’re not the same.

A hazard is anything with the potential to cause harm. It could be a physical thing like a trailing cable, a substance like a cleaning chemical, or even a work practice like repetitive manual lifting. It’s the source of the danger.

A risk, on the other hand, is about probability and severity. It’s the likelihood that a hazard will actually hurt someone, combined with how serious that harm could be. That trailing cable is a hazard, sure, but the risk it poses is low in an empty storeroom and dangerously high in a busy hallway.

In essence, a hazard is the “what” that can cause harm, and risk is the probability and severity of that harm occurring. Making this distinction sharpens your focus on the most pressing dangers.

This fundamental separation is what lets you prioritise your efforts. Instead of trying to eliminate every single hazard (which is often impossible), you can focus your energy on controlling the most significant risks.

Why This Process Matters

The goal here isn’t to create a completely risk-free workplace—that’s just not realistic. Instead, the risk assessment process gives you the power to make informed decisions and take sensible steps to protect your team and the business itself. It’s all about managing risks in a planned, organised fashion.

To make these terms crystal clear, let’s lay them out. Understanding these building blocks is the first step to creating a solid foundation for the entire process.

Core Concepts of Risk Assessment

| Term | Simple Explanation | Practical Example |

|---|---|---|

| Hazard | Anything that has the potential to cause harm. | A wet floor in an office corridor. |

| Risk | The chance (high or low) that someone will be harmed by the hazard, and how severe the harm could be. | An employee slipping on the wet floor and breaking an arm. |

| Control Measure | An action taken to eliminate the hazard or reduce the level of risk. | Placing a “Wet Floor” sign and mopping up the spill promptly. |

Once you’re comfortable with these key ideas, the rest of the risk assessment journey becomes much more straightforward. You’re no longer just reacting to problems; you’re actively preventing them.

Why a Formal Risk Assessment Is a Business Imperative

It’s one thing to understand the theory of risk assessment, but the real question is why your business should invest time and resources into a formal process. Let’s be clear: this isn’t just about ticking a box for auditors. It’s a fundamental part of smart, strategic business management.

A formal process is what moves you from constantly fighting fires to proactively preventing them in the first place.

This shift from reactive to proactive is massive. Instead of scrambling to deal with the fallout from an accident or a data breach, you’re anticipating what could go wrong and putting measures in place to stop it. This doesn’t just save money; it protects your team and safeguards your brand’s reputation from the kind of damage that can take years to repair.

Beyond Compliance to Strategic Advantage

While meeting legal and regulatory standards is often the initial push, the true value of a formal risk assessment lies in the tangible business results it delivers. A well-executed assessment does far more than just keep you on the right side of the law.

It directly leads to:

- Reduced Accidents: By identifying workplace hazards before they can cause harm, you create a safer environment. This naturally boosts morale and productivity.

- Minimised Downtime: Spotting operational risks—from potential equipment failure to supply chain hiccups—allows you to build resilience and avoid costly interruptions to your business.

- Enhanced Decision-Making: When leadership has a clear picture of potential risks, they can make much more informed strategic decisions about everything from new projects to market expansion.

In India, this structured approach is becoming increasingly critical. The Factories Act of 1948 has long emphasised safety, but the broader culture of formal risk assessment is still growing. Data from the National Crime Records Bureau (NCRB) showed around 17,000 industrial accidents in 2019. The alarming part? Poor risk assessment was a major factor in over 40% of those cases, highlighting the severe cost of neglect.

The real imperative for a risk assessment process is that it transforms risk from an unpredictable threat into a manageable business variable. It’s the difference between navigating a storm with a map and compass versus sailing blind.

Ultimately, neglecting this process is a gamble few businesses can afford to take. The potential costs—from legal penalties and operational losses to lasting reputational harm—far outweigh the investment required to manage risks effectively. Understanding your business compliance obligations is a key part of this strategic framework. Embracing a formal risk assessment process is essential for any organisation aiming for sustainable success and a robust bottom line.

The 5 Steps of an Effective Risk Assessment Process

Diving into a formal risk assessment doesn’t have to be overwhelming. It’s not about complex charts and endless paperwork. By breaking it down into a logical, five-step framework, you can turn a daunting challenge into a routine, manageable process for your entire organisation. Think of it as a roadmap that guides you from spotting potential trouble to building a stronger, safer workplace.

Step 1: Identify the Hazards

The whole journey kicks off with a simple act: observation. This first step is all about systematically identifying everything in your workplace that has the potential to cause harm. You need to think broadly here, because hazards aren’t just the obvious physical dangers we see in safety posters.

Look out for a few different types:

- Physical Hazards: These are the easy ones to spot. Think trailing cables, machinery without safety guards, poor lighting in a storeroom, or excessive noise on a factory floor.

- Chemical Hazards: This covers any exposure to cleaning fluids, industrial solvents, or other substances that could be harmful if handled incorrectly.

- Biological Hazards: Crucial in sectors like healthcare or food service, these are risks from bacteria, viruses, or other organic matter.

- Procedural Hazards: Sometimes, the danger is in the way work is done. This includes risks from manual handling, repetitive tasks that cause strain, or even unchecked workplace stress.

One of the best ways to get this done? Walk the floor. Talk to the employees who are doing these jobs day in and day out. They know the near-misses and the daily frustrations better than anyone. Don’t forget to check your accident and incident reports, either—they’re a goldmine of information.

Step 2: Analyse Who Might Be Harmed and How

Once you’ve got a list of hazards, the next logical question is, “So what?” To answer that, you need to figure out who might be harmed by each hazard and exactly how that harm could happen. It’s not enough to just say a machine is dangerous; you have to be specific about how it could injure someone.

For example, a wet floor isn’t just a hazard. The real risk is that employees, visitors, or delivery personnel could slip, fall, and suffer injuries from minor bruises to serious fractures. Getting this level of detail is absolutely critical for the next steps.

It’s also important to think about groups who might be particularly vulnerable. This could include new or young workers who aren’t familiar with the risks, expectant mothers, or team members with disabilities. Their specific needs might require special consideration.

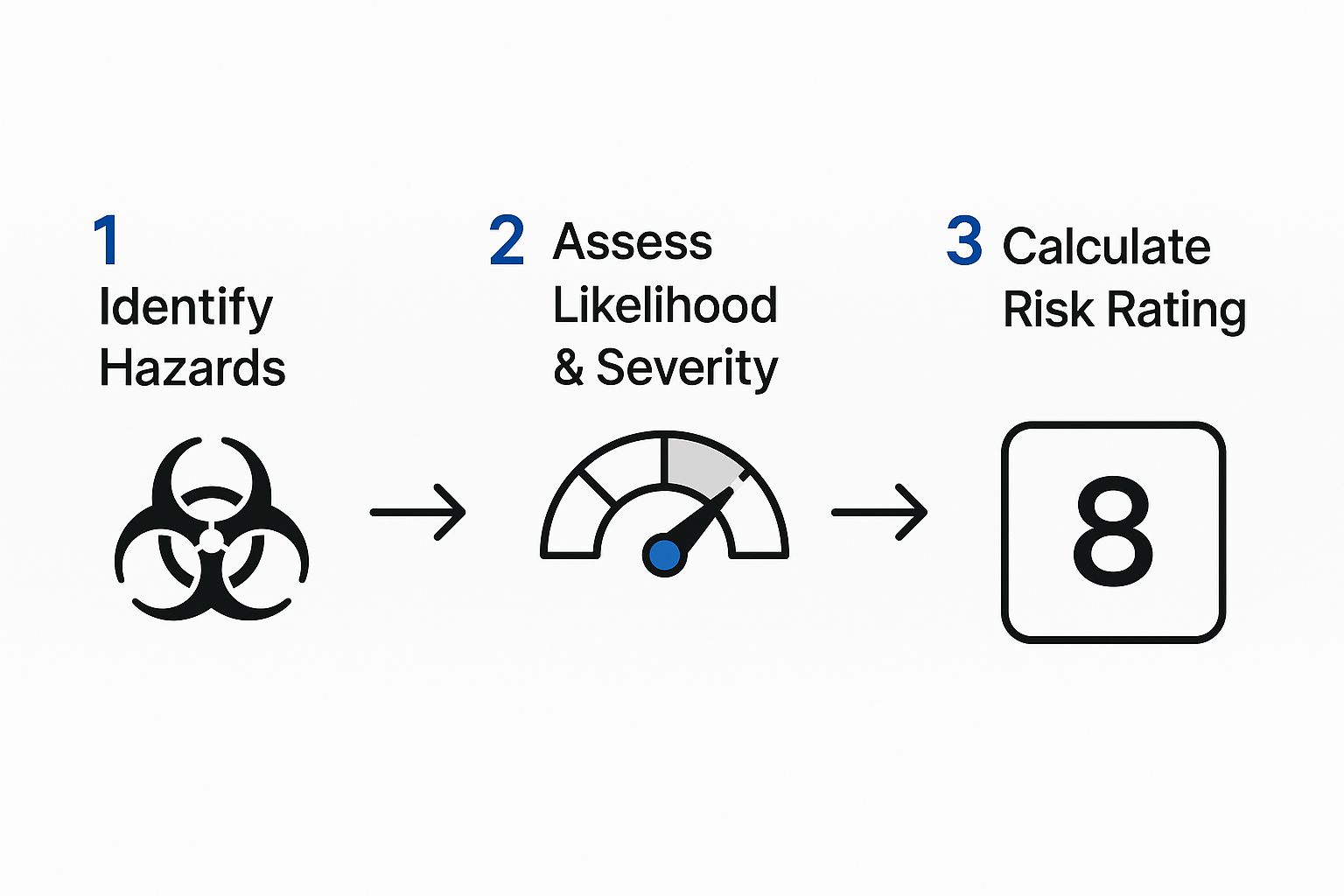

This simple infographic really nails the core logic of moving from spotting a hazard to giving it a risk rating.

This visual flow shows you how to connect a potential danger to its likelihood and severity—the very foundation of prioritisation.

Step 3: Evaluate the Risk and Prioritise

With a clear picture of the hazards and the harm they could cause, it’s time to evaluate. This is where you estimate two key things: the likelihood of something bad happening and the severity of the outcome if it does.

A common way to tackle this is with a simple risk matrix. You score both likelihood and severity (say, on a scale of 1-5). Multiplying these two numbers gives you a risk rating, which instantly shows you what to focus on first. A hazard with high likelihood and high severity (like an exposed electrical wire in a busy hallway) demands immediate action. A low-likelihood, low-severity risk can be dealt with later.

Prioritisation is the strategic heart of the risk assessment process. It ensures you focus your limited resources—time, money, and effort—on the dangers that pose the greatest threat to your people and operations.

Step 4: Implement Control Measures

Now it’s time for action. You’ve prioritised your risks, so the next move is to decide on and implement the right control measures to either eliminate the hazard completely or, at the very least, reduce the risk to an acceptable level.

The best way to think about this is using the “hierarchy of control,” which is just a fancy way of saying “start with the most effective fix first.”

When you’re trying to control a risk, there’s a pecking order for the most effective solutions. This “Hierarchy of Control” gives you a clear framework, starting with the strongest defence and moving down to the last line of protection.

Hierarchy of Control Measures

| Control Level | Description | Example |

|---|---|---|

| Elimination | Physically remove the hazard entirely. This is the most effective control. | Instead of having employees work at height, use extendable tools from the ground. |

| Substitution | Replace the hazardous item or process with a safer alternative. | Use a less toxic cleaning solvent. |

| Engineering Controls | Isolate people from the hazard by making a physical change to the workplace. | Install guards on machinery or ventilation systems to remove harmful fumes. |

| Administrative Controls | Change the way people work to reduce exposure to the hazard. | Implement safety training, rotate jobs to limit exposure time, or add warning signs. |

| Personal Protective Equipment (PPE) | Provide workers with equipment to protect them from the hazard. This is the last resort. | Require employees to wear safety glasses, gloves, or hard hats. |

By following this hierarchy, you ensure you’re not just putting a temporary patch on the problem but are implementing the most robust and lasting solution possible.

In today’s business world, this isn’t just about physical safety. It extends to people risks, too. For instance, putting robust identity verification services in place is a critical control measure to mitigate the risk of bringing fraudulent candidates into your organisation.

Step 5: Review and Update Regularly

Finally, remember that a risk assessment isn’t a “one and done” task. It’s a living document that needs to adapt as your business does. Workplaces are always changing—new equipment gets installed, processes are updated, and new people join the team.

Because of this, you have to regularly review your assessment to make sure it’s still relevant and effective. It’s good practice to schedule a review at least once a year. You should also revisit it anytime there’s a significant change, like bringing in new machinery or after an accident or a near-miss. This continuous loop of review and update ensures your safety measures keep pace with your business.

Risk Assessment in Action Across Indian Industries

The theory behind risk assessment really comes alive when you see it applied to real-world challenges. Across India, different industries take this universal framework and adapt it to manage their own unique weak spots, showing just how flexible and powerful it is.

From the noisy floor of a factory to the quiet corridors of a hospital, the core ideas of identifying, analysing, and controlling risks are always the same. Seeing these principles in action helps cement what a risk assessment truly is: a practical tool for keeping people, property, and operations safe.

Let’s look at a few concrete examples from different Indian sectors.

Manufacturing and Industrial Safety

Picture a massive automotive manufacturing plant in Pune. The place is buzzing with heavy machinery, automated assembly lines, and various chemicals, creating a long list of potential dangers.

Here, risk assessment isn’t just an annual formality; it’s a daily reality.

- Hazard Identification: Supervisors and safety officers are constantly walking the floor, spotting risks like a machine with an unguarded moving part, an oil spill creating a slip hazard, or flammable materials stored improperly.

- Risk Analysis & Evaluation: They then evaluate each hazard. That unguarded machine part? That’s a high risk because an injury would be severe, and workers are always nearby. A small spill in a corner with little foot traffic might be rated lower, but it still needs to be dealt with.

- Control Measures: The first priority is engineering controls, like installing physical guards on the machines. This is backed up by administrative controls, such as mandatory safety training for all operators and clear signs marking danger zones.

This non-stop cycle of assessment directly cuts down on workplace accidents, protects employees, and prevents expensive shutdowns. It proves its worth on the factory floor every single day.

Public Safety and Disaster Management

The value of risk assessment goes far beyond private companies and into the world of public safety. In states like Kerala, which are prone to heavy monsoons and flooding, disaster management authorities lean heavily on this process to protect entire communities.

The National Disaster Management Authority (NDMA) of India now requires these assessments for all district-level planning. After the devastating Kerala floods of 2018, risk assessments became essential for pinpointing vulnerable, low-lying areas and figuring out where to invest in infrastructure.

A 2020 study found that these post-flood assessments helped slash emergency response times by 25% and improve the distribution of critical resources by 33%.

Healthcare and Patient Safety

In a busy multi-speciality hospital in Delhi, the risks are completely different but no less critical. The focus shifts to patient safety, stopping the spread of infections, and preventing medical errors.

A hospital’s risk assessment would identify hazards like healthcare-associated infections (HAIs), medication mix-ups due to similar-looking packaging, or patients falling out of bed.

By analysing these risks, the hospital can put solid controls in place. These might include strict hand-washing rules, a double-check system for giving out high-risk medicines, and installing bed rails for patients who need them.

By systematically assessing risks, healthcare facilities transform from a reactive environment that treats illnesses to a proactive one that actively prevents harm.

Modern Hiring and People Risk

Today, risk assessment is also a vital tool in human resources, especially when it comes to hiring. Companies know that bringing the wrong person on board can create huge risks, from fraud and workplace misconduct to serious damage to their reputation.

This is where background verification acts as a crucial control measure.

In the fast-growing financial technology space, for example, checking a candidate’s financial and criminal history isn’t just a good idea—it’s essential for managing risk. By understanding how to approach hiring in the fintech industry, companies can build a trustworthy team right from the start. This modern application shows just how much the principles of risk assessment have evolved to tackle today’s business challenges.

Best Practices for a Meaningful Risk Assessment

Simply ticking boxes on a risk assessment checklist won’t get you very far. To turn it from a routine task into a truly powerful management tool, you need to weave some core best practices into your approach. These aren’t just extra steps; they’re principles that ensure your assessment is thorough, accurate, and actually leads to real improvements.

The single most important practice? Involving employees at every level. The people on the ground—those operating machinery or dealing with clients every day—have a perspective on risks that managers in an office simply can’t see. Their insights are gold for building a complete and realistic picture of potential hazards.

Foster a Collaborative Environment

A great risk assessment is always a team sport. When you bring diverse viewpoints together, from the factory floor to the executive suite, you build a much stronger, more complete understanding of the organisation’s risk landscape. This kind of collaboration also does wonders for building a safety-first culture where everyone feels a sense of ownership.

To get this collaboration right, you need to focus on a few key things:

- Clear Communication: Make sure everyone knows why you’re doing the risk assessment and how their input makes a difference. When people understand the purpose, they’re far more likely to engage.

- Proper Training: Your team is your first line of defence, but only if they’re equipped with the right knowledge. Train them on how to spot and report hazards effectively.

- Practical Tools: Don’t overcomplicate things. Use simple, straightforward tools like risk matrices and checklists to standardise the process. This makes it easier for everyone, regardless of their role, to participate.

Maintain Diligent Documentation and Regular Reviews

A risk assessment starts losing its value the second it gets filed away and forgotten. Meticulous documentation isn’t just about compliance; it’s about creating a historical record. This record helps you track trends and see if your control measures are actually working over time. Think of it as your proof of due diligence.

But a document that just gathers dust on a shelf is useless.

A risk assessment should be treated as a living document, not a one-time project. Regular reviews are essential to keep it relevant and effective in a constantly changing business environment.

Plan to review your assessment at least once a year. More importantly, trigger a review anytime there’s a significant change—like bringing in new equipment, altering a work process, or after an incident occurs. This ensures your safety measures always match your current reality.

In India’s healthcare sector, for example, we’re seeing a positive shift towards institutionalised risk committees. Around 62% of major hospitals in metropolitan areas now have them, using a mix of qualitative and quantitative tools. When implemented well, this approach can slash adverse events by 20-30%. Discover more about these risk assessment findings.

Common Questions About the Risk Assessment Process

As you start getting your head around the risk assessment process, a few questions always seem to pop up. Let’s tackle them head-on, so you can move from theory to practice with confidence.

How Often Should We Review Our Risk Assessments?

This is a big one. A risk assessment isn’t a “set it and forget it” document. Think of it as a living part of your business strategy, something that needs regular check-ups to stay relevant.

As a rule of thumb, you should conduct a full review at least once a year. But—and this is important—certain events should trigger an immediate review, no matter when your last one was.

These triggers are usually signs of significant change in your workplace:

- Introducing new equipment or machinery: Fresh tech brings fresh hazards that need to be understood and managed.

- Changing work processes or procedures: Shaking up how a job gets done can create risks you hadn’t considered before.

- After an accident or near-miss: An incident is a massive red flag that your current controls might not be working as they should.

- Hiring new categories of employees: Different groups, like young workers or temporary contractors, might face unique risks.

Treating your assessment like a dynamic tool is the only way to make sure it’s actually protecting your people and your business.

Can Small Businesses Do This Effectively?

Absolutely. The beauty of the risk assessment process is that it’s completely scalable. For a small business, this doesn’t need to be some complex, software-driven affair run by a dedicated department.

The core principles of spotting, analysing, and controlling risks are universal.

A small business owner can perform a powerful assessment just by walking through their space with a critical eye, talking to their employees, and jotting notes on a simple template. It’s the mindset that counts, not the company’s size. In fact, smaller outfits can often be more nimble in putting fixes in place once a risk is identified.

For small and medium businesses, the focus should be on practicality over paperwork. A simple, well-thought-out assessment that leads to real change is worth far more than a hundred-page document that just gathers dust.

What are Some Common Mistakes to Avoid?

Knowing where others have gone wrong is a great way to get it right the first time. One of the most frequent mistakes is making risk assessment a solo mission. It should be a team sport. If you don’t involve the people doing the work every day, you’re guaranteed to miss crucial insights.

Another common pitfall is being too generic. A risk assessment for an office that just lists “slips and trips” is pretty useless. It needs to be specific: “risk of tripping over loose printer cables near the main walkway.”

Finally, a lot of organisations fall at the final hurdle. They do a great job identifying risks but then fail to follow through with implementing and monitoring the controls. An assessment without action is just an academic exercise. Avoid these traps, and you’ll make the whole process truly meaningful.

A robust background verification process is a critical control measure for mitigating hiring risks. SpringVerify offers fast, reliable, and compliant background checks to help you build a trustworthy team with confidence. Learn more at SpringVerify.